Not known Factual Statements About Freezer Refrigerator Inverter

Wiki Article

Getting My Freezer Refrigerator Inverter To Work

Table of ContentsThe Basic Principles Of Freezer Freon The Buzz on Direct Cooling FreezerSome Ideas on Freeze Dryer You Need To KnowThe Best Guide To Freeze Dryer

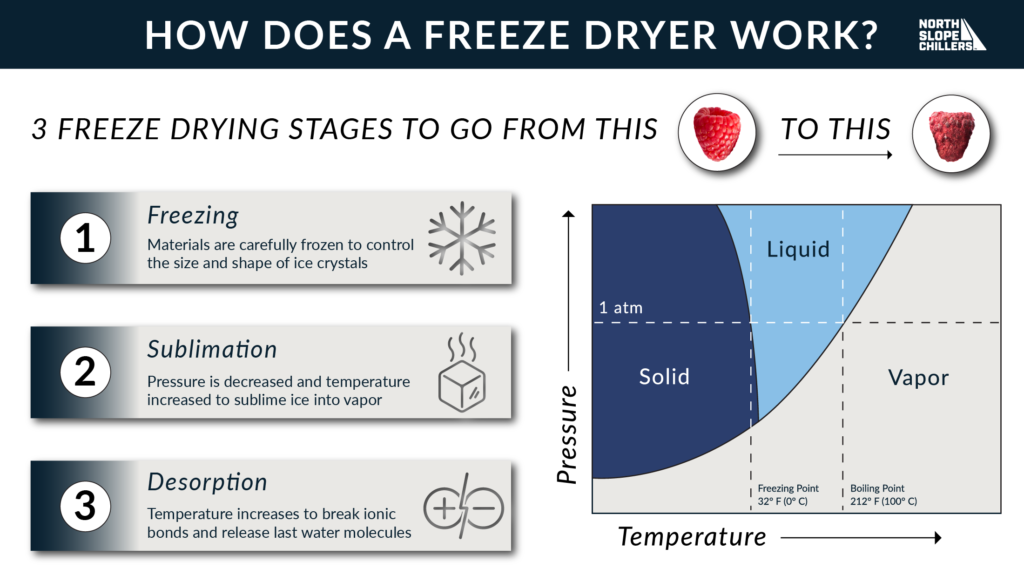

Freeze-drying or lyophilization is a dehydration method based upon the sublimation of water in a product (, ). This suggests that the item's water web content changes from a solid to an aeriform state or from ice to vapor without going through the liquid state (). Freeze-drying is considered a premium quality dehydration technique for a number of reasons, including (, ): it operates at low temperatures, which adds to maintaining an item's dietary worth, taste, look, and also heat-sensitive compoundsfreezing inhibits chemical and also microbiological processes, which significantly delays the item's deterioration (consequently extending its service life) Raw foods are consisted of about 80%95% water, which can be split right into "free" as well as "bound" water.In the freeze-drying process, all totally free water as well as some bound water should be eliminated, as well as complimentary water must remain frozen in any way times. As a matter of fact, this is the main difference between freeze- and vacuum-drying and also one of the most challenging action (). The freeze-drying process can be split into 3 actions (,, ): The product is frequently frozen under atmospheric stress.

Known as desorption drying out, it's the drying out of products to their preferred moisture by removing the remaining bound water - direct cooling freezer. Freeze-drying must be performed in regulated conditions that do not melt the water, seeing that the presence of fluid water may alter the product's composition, shape, as well as physical residential or commercial properties ().

Freeze drying takes place in 3 phases: Icing up Main Drying (Sublimation) Second Drying (Adsorption) Proper freeze drying can lower drying out times by 30% Freezing is one of the most vital stage of freeze drying out, and there are lots of methods for it. Cold can be carried out in a freezer, a chilled bathroom (covering freezer) or on a rack in the freeze dryer (cooler).

The smart Trick of Freezer Freon That Nobody is Talking About

Freeze drying out is easiest to achieve using big ice crystals, which can be produced by slow-moving freezing or annealing. With biological materials, when crystals are also large they may break the cell walls, and also that leads to less-than-ideal freeze drying results.

Freeze drying's final phase is additional drying out (adsorption), throughout which the ionically-bound water particles are removed. By elevating the temperature level greater than in the key drying phase, the bonds are broken between the product and the water particles.

After the freeze drying out process is full, the vacuum can be braked with an inert gas prior to the product is sealed. A lot of products can be dried out to 1-5% recurring moisture.

Getting My Freeze Dryer For Home To Work

The essential concept in freeze-drying is sublimation, the shift from a strong directly right into a gas. Similar to dissipation, sublimation occurs when a molecule gains sufficient energy to damage without the particles around it. Water will sublime from a blog strong (ice) to a gas (vapor) when the molecules have sufficient energy to damage complimentary however the problems aren't right for a fluid to develop (freeze dryer).For a compound to take any type of specific stage, the temperature level and pressure must be within direct cooling freezer a certain variety. The chart listed below programs the essential stress and also temperature values of different stages of water.

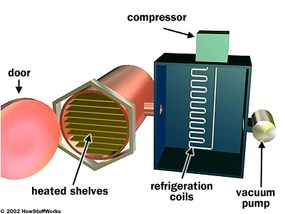

06 atmospheres (ATM MACHINE), the water is warm sufficient to thaw, but there isn't enough stress for a fluid to form. It becomes a gas. This is exactly what a freeze-drying maker does. A normal machine consists of a freeze-drying chamber with a number of racks affixed to warming units, a cold coil linked to a fridge compressor, and also an air pump.

When you secure the chamber and also begin the procedure, the maker runs the compressors to decrease the temperature level in the chamber. The material is frozen solid, which separates the water from whatever around it, on a molecular degree, despite the fact that the water is still existing. Next off, the maker switches on the vacuum cleaner pump to require air out of the chamber, lowering the air pressure below.

Some Known Details About Freezer Temperature

Since the stress is so reduced, the ice transforms straight into water vapor. The water vapor condenses onto the cold coil in solid ice form, in the same means water condenses as frost on a chilly day.

Yes, they are indeed amongst the extra pricey food conservation techniques. It's important to understand that freeze drying out is various than drying out.

The other day a close friend asked me if I'm as thrilled about it as I was when I initially got it. Well, I'm even more fired up really, as well as after that conversation, I went out and bought a second device! To be sincere, I wasn't really ecstatic regarding the freeze dryer in the beginning.

Report this wiki page